Agricultural cellulose esters

Agricultural cellulose esters

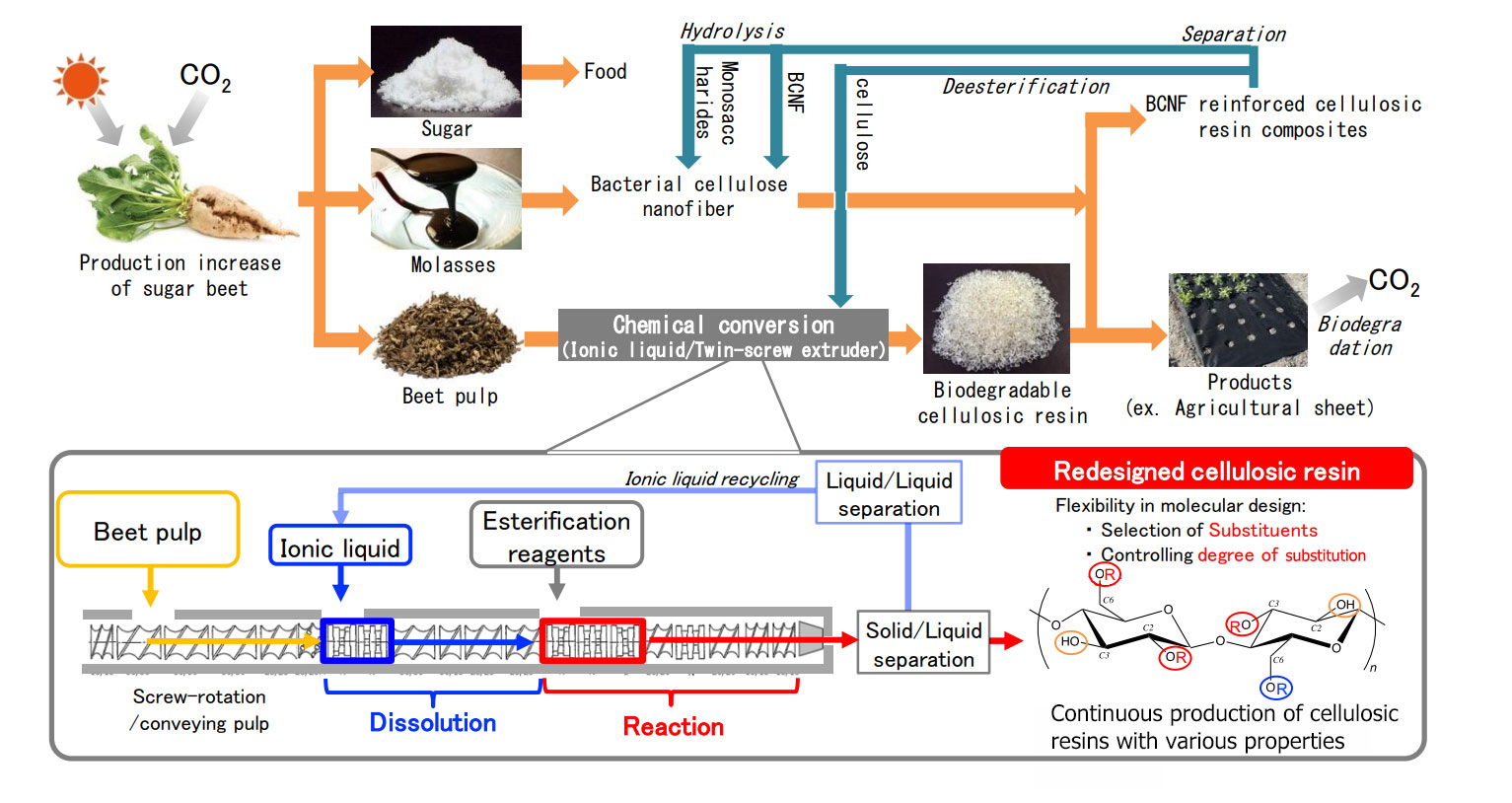

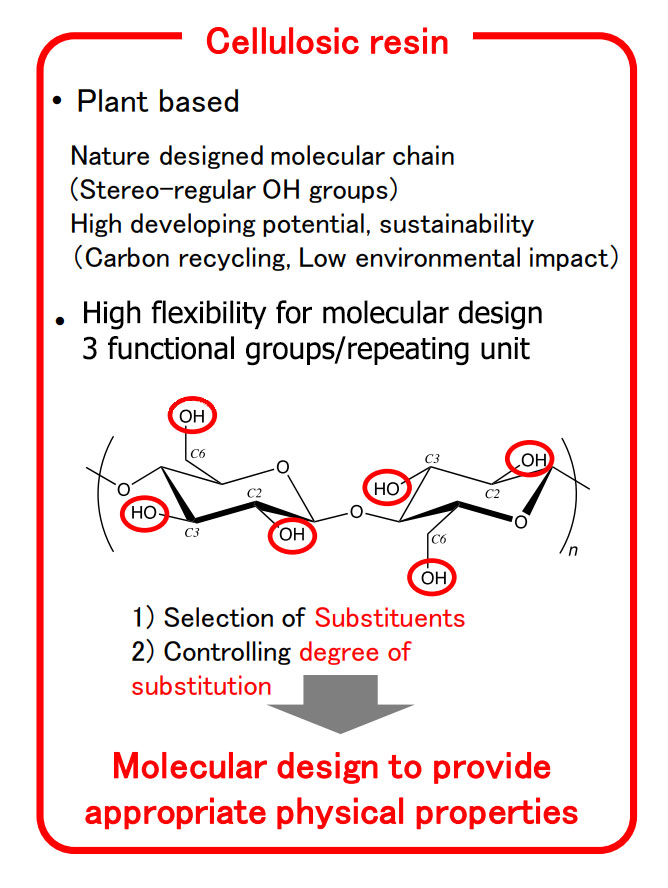

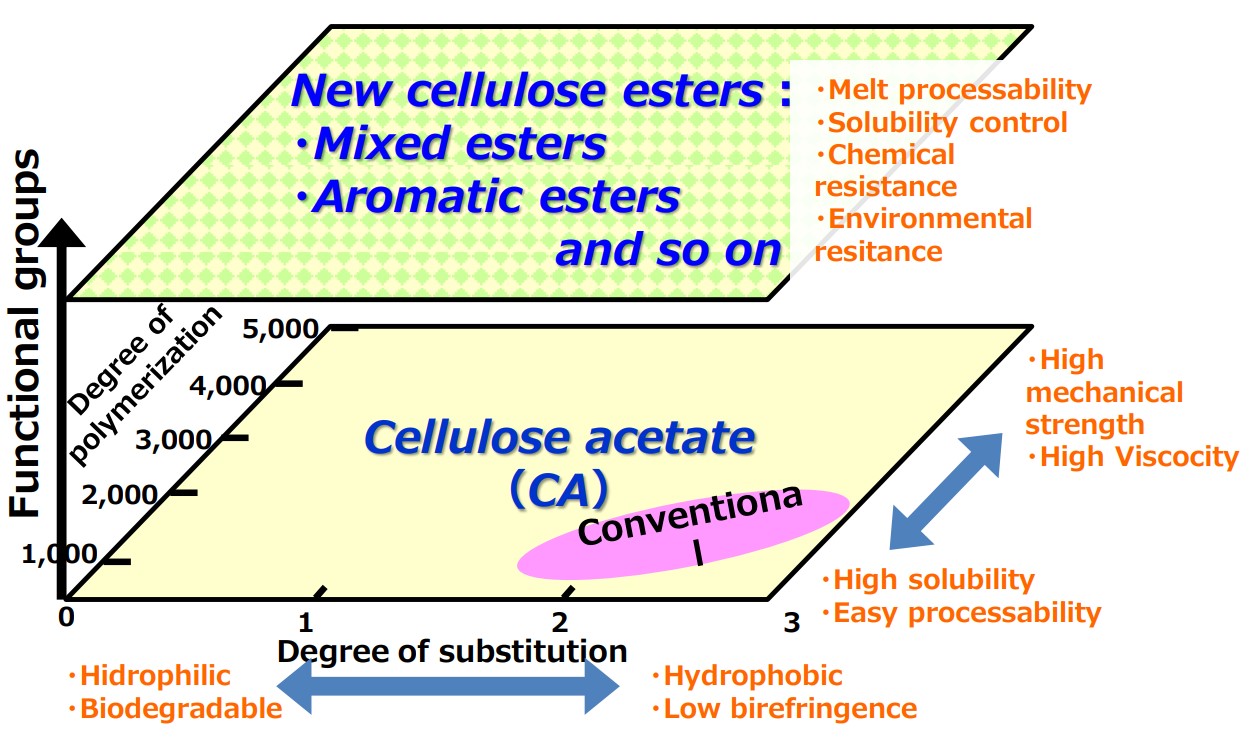

Redesigning cellulosic resin

High flexibility for designing cellulosic resins

Advantages over existing bioplastics

|

|

Biopolyethylene (bioPE) |

Polylactide(PLA) |

Starch resin |

Conventional cellulose acetate (CA) |

Redesigned cellulosic resin |

|

Raw material |

Sugarcane |

ex. Corn |

ex. Corn |

Wood pulp |

Agricultural waste |

|

Designability |

None |

None |

Moderate |

Low |

High |

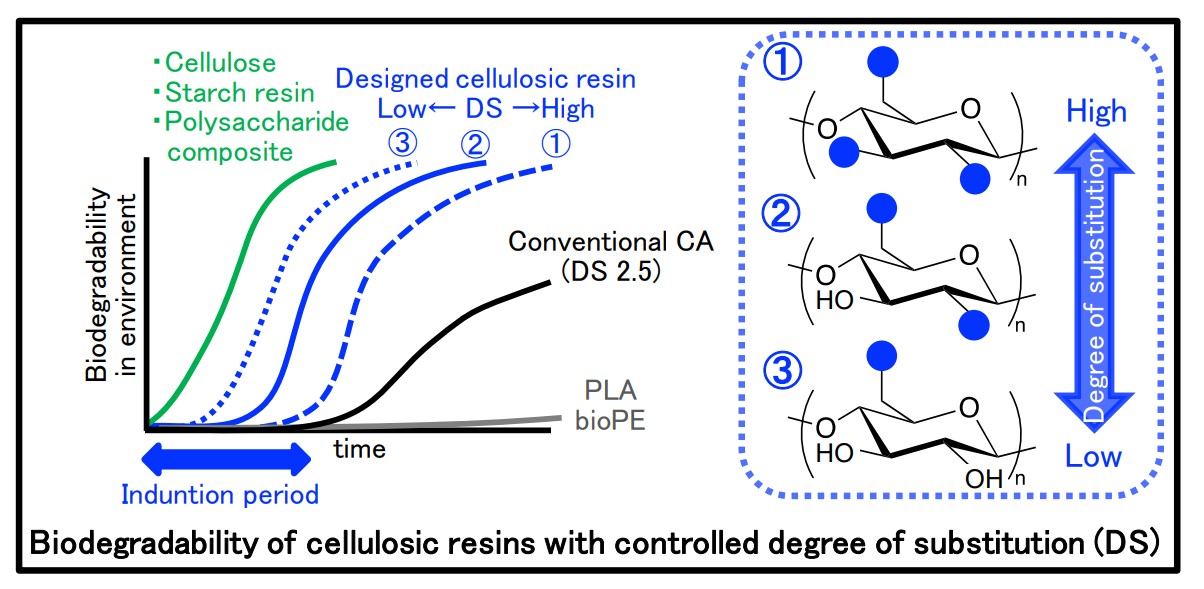

Biodegradability of cellulosic resin

Advantages over existing bioplastics

|

|

Biopolyethylene (bioPE) |

Polylactide (PLA) |

Starch resin |

Conventional cellulose acetate (CA) |

Redesigned cellulosic resin |

|

in Soil |

none |

only in Composting |

moderate |

Long induction period |

Controllable induction period |

|

in Ocean |

none |

none |

moderate |

Long induction period |

Controllable induction period |

Biodegradability of cellulosic resins with controlled degree of substitution (DS)

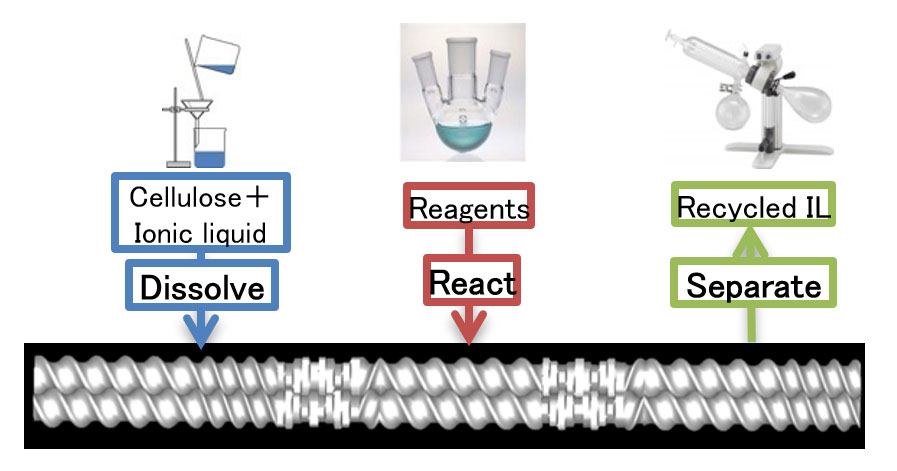

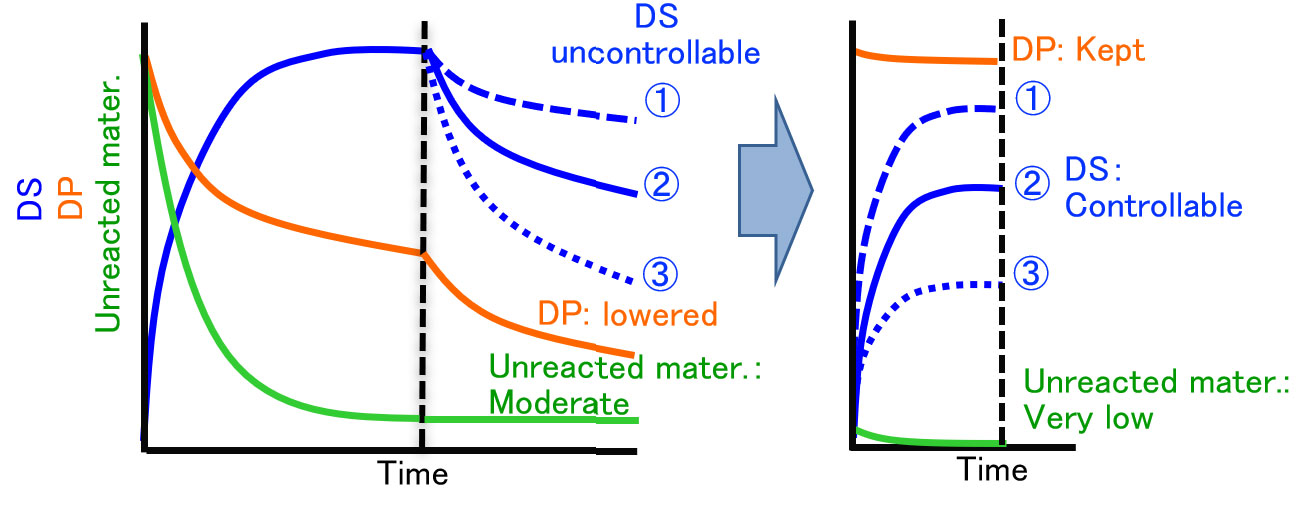

Productivity of Cellulosic Resins -Innovations in Ionic Liquid (IL)/Reacive Extrusion (REX) Method-

Advantages of IL/REX method over conventional methods for producing cellulosic resins

|

|

Conventional method |

IL/REX method |

|

Production step |

Multi steps |

One step |

|

Production time |

48 hours |

within 10 min |

|

Substitution |

Only One at same time |

Multi at same time |

|

DS control |

Uncontrollable |

Arbitrarily controllable |

|

Flow synthesis |

Impossible |

Possible |

|

Unreacted raw material |

Moderate |

Very low |

|

Decrease of degree of polymerization (DP) |

High |

Very low |

| Conventional |

IL method |

|

|

Esterification |

Deesterification |

Esterification |

- Continuous production in a short time

Energy saving, High productivity - Low material loss

High efficiency, low environmental impact - General machine

Easy to be popular